Cake Pumps

AESOps Cake Pumps - Meadowhead

AESOPS were experiencing a number of problems with their cake pumps and had decided that a potential change of supplier may be prudent.

A life span of 6 months on stators and 2 years on rotors was compounded not only by the cost of the parts, but the fact that servicing involved a very large 10” elbow to be removed, requiring lifting equipment.

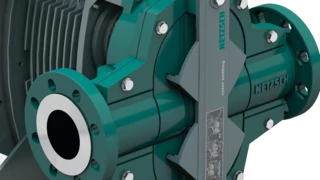

We will show you how you can benefit from the service-friendly NEMO® BT immersible pump and make your process more efficient.

Individual Consulting

Criteria for a successful alternative supplier

1. Increase the MTBF (mean time between failures)

2. Reduce the spend on spare parts

3. Make maintenance easier

4. Reduce energy costs where possible

Solution

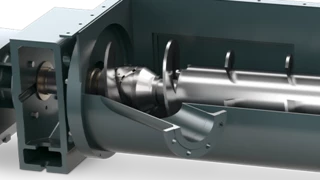

1. Whilst rotor and stator wear are a factor, the main decrease in flow had been identified as wearing of the front 3-4 flutes of the pump auger in the suction housing. The previous suppliers unit is designed for a 150% fill rate, this means that 50% of the sludge carried forward recirculates in the pumps compression zone. The result is that the first 3-4 flutes work 50% harder than the rest of the auger.

This is one of, if not the highest cost spare part on the pump.

In comparison, the NETZSCH pump auger is ‘timed’ so that there is 100% filling of the rotor/stator, minimising the recirculation within the pump, and keeping the wear rate of the auger to a minimum.

2. NETZSCH spare parts work out at around a 50% lower cost.

3. The discharge pressure of the system is max 10 bar. For selection purposes you would not use a 12 bar pump and the next size available within the competitors range is a 24 bar pump.

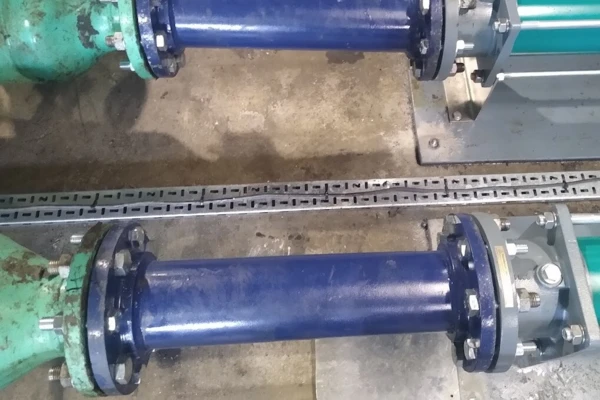

NETZSCH has an 18 bar version available within its standard range, meaning that the pump footprint can be shortened in length and the customer is then able to add a spool piece between the large 10” elbow and the pump. Now when maintenance is needed, the spool piece can be detached and no lifting equipment is required as the components can be removed horizontally.

4. Using the amps pulled, rpm and discharge pressure – we were able to calculate the absorbed power of the competing unit. Using the same information, we were also able to establish that NETZSCH could save the site over £5,000 per year per unit on electrical costs alone.

Other Benefits

To make the installation as easy as possible for the site, NETZSCH matched the overall height of the pump, the hopper dimensions and even the drilling positions.

Essentially, this made the pump a straight in and out swap, which was concluded on two pumps within one weekend.

Quotation from the client: “Working with Netzsch pumps and their partners has been a pleasure, good knowledgeable people who are passionate about their product and the product is superb, hard to look at other options.”

Operating at 30%, one pump was able to achieve the flow of two of the competitors units both running at 80%.

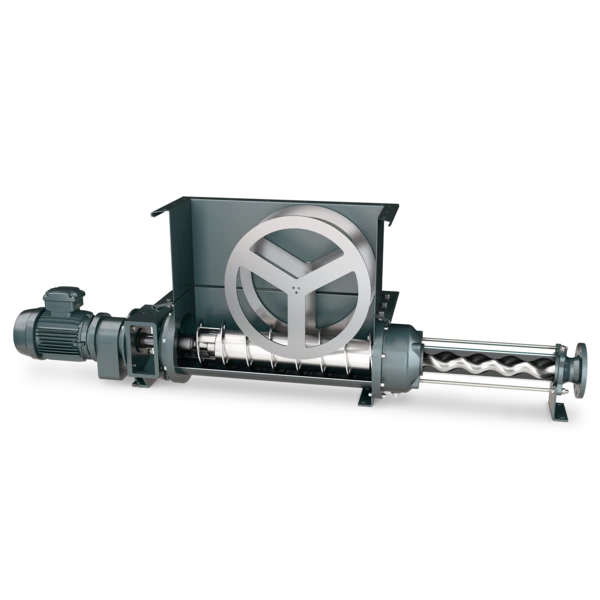

NEMO® BF Hopper Shaped Pump With optional aBP-Module®

- Medium: Dewatered Sludge

- Max Flow: 10 m³/h

- Max Pressure: 10 bar

- Dry Solids Content: 20 - 30%